Das hier ist ein Prospekt der BTS/Philips aus 1994

Und eigentlich werden hier die internen (inneren) Vorzüge der Philips LDK 10 Studio-Kameras ausführlich beleuchtet. Die LDK 10 war der optisch fast baugleiche Nachfolger der Philips LDK 9, die nach der Migration von Bosch Fernseh Darmstadt und Philips Broadcast Breda die Fese/BTS KCM 125 Röhrenkamera abgelöst hatte.

Die Philips CCD Kameras waren schon um einige Klassen besser, was die Wandlung des optischen Bildes in ein Standrd Fernsehsignal anging. Über die anderen Qualitäten der Bedienung stritten die "Experten". Doch für BTS waren die Würfel bereits gefallen, Darmstadt hatte sowieso den digitalen Zug verschlafen oder auch nur ignoriert.

Der CCD Chip ist wie beim Hifi-Plattenspieler der Tonabnehmer (oder Abtaster) das wichtigste zentrale Bauelement. Und auf diesem Gebiet waren die Philips Labors in Breda eine ganze Zeit lang weltweit führend.

SENSORS von BTS Breda BV 1994.

Diese Broschüre ist in englischer Sprache.

.

BTS CCD sensors with

DYNAMIC PIXEL MANAGEMENT SENSORS

.

- 2/3 inch sensor remotely switchable from 4:3 to 16:9 and back again

- 1000 pixels per line in both formats - no loss of horizontal and vertical resolution or change in horizontal angle of view

- No smear or vertical highlight streaks to spoil pictures - even with short electronic exposure times

- Horizontal reverse scan mode

- No shift registers in the image plane with Frame Transfer techniques -so no lag

- No lag guarantees very high dynamic resolution

- High sensitivity without using micro lenses on the sensor - 2000 Lux at f8

- Linear sensitivity and high resolution across the full range off-stops for maximum sensitivity and optimum resolution - under all conditions

- Very high dynamic range - 600% almost double any other 1000 pixel sensor

- International CCD camera lens standard enables lens exchange

.

DPM - the future of sensor technology

As pioneers, some 25 years ago, of the original CCD technology, it is perhaps hardly surprising that today, BTS and Philips are once again setting the standards for tomorrow's television industry. With a concept that will revolutionize traditional views on camera sensors.

DPM - Dynamic Pixel Management.

A totally new concept that meets today's 4:3 broadcasting needs, and also those of tomorrow's widescreen 16:9 productions. In a single 2/3 inch, 1000 pixels per line Frame Transfer sensor.

A sensor that means you can switch from one format to another - and back again. With the same exceptional standards of resolution plus no lag or smear performance, whatever format you're shooting in.

The new DPM sensor has been made possible by combining the skills and resources of BTS and the Philips Image Technology Center. The one organisation with an unrivalled knowledge and experience in understanding the broadcast industry's needs. The other, with one of the world's top high technology facilities dedicated to advanced sensor design and production.

Today, with television moving into the age of widescreen transmissions, companies are looking to use existing sensor designs to provide the 16:9 solution for the cameras of tomorrow. In the short term, some of these solutions appear to offer adequate answers.

To take full advantage of potential picture performance as seen on EDTV systems, much better sensor performance is needed. But at the same time, the current requirements of the 4:3 users cannot be compromised.

DPM - the no compromise solution

At the start of development of the new BTS sensor concept, one fundamental question had to be addressed. Why should camera users have to compromise when they need both 4:3 and 16:9 pictures?

BTS has now solved these problems

Up to now, the competitors' best solution has been to change optical blocks. In other words, use a dedicated 16:9 or a dedicated 4:3 version to suit both needs. This needless to say means that users also suffer all the associated time involved in changeover and resetting the camera.

Alternatively electronic conversion can be chosen, which whilst making "switching" faster adds costs and reduces the horizontal pixel count from 1000 down to 720 in a 4:3 format. Thereby losing horizontal resolution and causing a change in horizontal angle of view.

The solution - DPM or "Dynamic Pixel Management" - lies in the application of proven Frame Transfer technology techniques. And then managing the pixels in a way never before considered. A way that is not possible by applying other sensor technology to the problem.

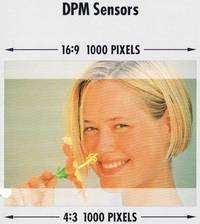

The diagram illustrates a 2/3 " sensor chip with vertical columns of pixels. 1000 columns across the sensor surface, and thus 1000 pixels per line. So far, FT and other current approaches have similarities.

Ask the question how can both 4:3 and 16:9 formats be accommodated by the same pixel configuration and technologies immediately diverge.

With the DPM - Dynamic Pixel Management system the vertical picture size changes. But the 1000 pixel columns across the sensor surface remain the same, and the aspect ratio is controlled by a simple switch on the Master Control Panel (MCP) or via an input signal to the Base Station. Switching provisions are also provided by a locally protected control at the camera head on the LDK 10P.

No change is required in camera set-up. And there is no change in horizontal angle of view. Other types of sensor concept cannot accommodate this leading technology. The sensors are dedicated - either to 4:3 or 16:9. With the DPM sensor from BTS, all that is needed is a push on a switch.

DPM in action

.

- No compromise performance - 4:3 or 16:9 switchable

- Horizontal reverse scan mode

- Unique auto black balance and shading

- Best highlight handling performance of any sensor

- Maximum sensitivity across the full f-stop range

- FT technology means no lag or smear

.

Unlike sensor technology based on the other current principles, the BTS Frame Transfer sensor concept means the same basic 2/3 inch sensor can be used in either 4:3 or 16:9 formats.

The vertical pixels being managed and automatically addressed to achieve the correct numbers of lines whichever format is selected. All the while maintaining 1000 pixels per line whether the choice is for 4:3 or 16:9.

In addition, with this technique, there is no change in horizontal or vertical resolution performance when switching from one aspect ratio to another. There is also no change in the horizontal angle of view.

Like other Frame Transfer sensors found across the total family of BTS cameras, black reference lines of pixels are found at the top and bottom of the image area. These lines are protected from incoming light, and give an accurate indication of temperature changes.

The reference signal from these pixels can be used in the camera to provide automatic compensation when applied to the video signal in the camera preprocessor. This process is carried out on a field by field basis and ensures a stable black level without the need for operator intervention.

Continuous on-line auto black balance and shading is unique to BTS cameras and enables very fast use of the camera from the moment of switch-on. Also vital for the successful use of cameras under all conditions (particularly in outside operations), is the ability of the sensor to handle highlights in the scene.

.

The dynamic range of the new DPM sensors ensures outstanding highlight handling performance - with exposures in excess of 600% being comfortably managed. Other 1000 pixel sensors barely exceed half that figure. The result is that high charge packets (that must be stored in the sensor electrodes) and which are caused by highlights, can be easily handled.

When it comes to camera sensitivity, the benefits of the DPM sensor technology are also distinct. Due to the relatively large pixel size (window size) of the 2/3 inch DPM sensor, when compared to other current sensors, the sensitivity of the new BTS concept is the same as its 2/3 inch competitors (2000 lux at f8) - but without the need to use on-chip micro lenses.

This means that with DPM technology, camera sensitivity is linear across the full range of camera lens f-stops. So maximum sensitivity and resolution are assured when they are most needed.

Frame Transfer sensors give the added assurance of absolutely no lag or smear. So dynamic resolution is optimum under all operating conditions, giving clean and clear pictures for slow or stop motion VT playback, or in standard panning shots.

In addition, a horizontal reverse scan mode is featured, so shots through mirrors can be made without external effects units being necessary.

Frame Transfer techniques - a closer study

For tomorrow's television and also today's, the unique switching capability of the new BTS DPM sensors represents a considerable technological achievement. An achievement that is made possible by using Frame Transfer techniques. Ones which have already been proven in use, in the existing range of BTS cameras. From compact portables, through to studio and EFP/Triax units, and on into the future with the 2.2 million pixels sensor for the BTS High Definition camera. But why Frame Transfer? The answer to which type of sensor meets needs best can be found by looking at critical factors affecting sensor performance - and thus picture quality.

Smear - eliminate or simply reduce it?

Other types of sensor have an intermediate store that permits fast transfer of image charges via a vertical shift register, into the store. This helps reduce smear.

The nature of the Frame Transfer concept however, means that smear is not just reduced - it simply does not exist.

The FT sensor construction is based around an image section, a storage area (intermediate store) and horizontal output shift register(s). The image pixels in the image section are used for integration, capture of the image, and for moving the charge packets quickly downwards into the storage area.

The problem of smear occurs during the vertical transfer of picture information - charge packets - from the image area of the sensor, using vertical shift registers, to the horizontal shift register. During this period there is a continual build-up of photo charge, with leakage of incoming light into the vertical shift registers. The result of this leakage is that electrons are generated.

Since the time taken to move one complete image down the vertical shift register to the horizontal shift register is governed by the clock frequency, vertical smear is caused by the leakage of electrons as they are shifted down the vertical register.

When the picture contains highlights, this phenonemon is particularly evident. With a vertical trail running from top to bottom of the complete picture. The Frame Transfer CCD with its 10-year garanteed shutter, is the only true solution to the smear problem. The Frame Transfer sensor moves charge packets rapidly from the image region to the storage region, during a small part of the internal vertical blanking. Without the shutter, some smear would still occur. With it, it can't. Because it is timed to operate during the shift of charge packets. Thus preventing any light from contaminating the next picture.

Other sensor technologies involve moving the charge packets, during the vertical blanking period, into adjoining shift registers next to the image pixels, and then on into the field memory. Due to this field memory, the vertical transfer rate can be considerably speeded up, and is not limited to field rate frequencies.

The result is that smear can be reduced to a claimed -116 dB. But not eliminated completely. Reducing exposure times down to say 1/2000 second, with the associated shortening of integration times, and smear increases again. By a factor of 40, or +32 dB at 1/2000 second and +26 dB at 1/1000 second.

A further problem is caused by having shift registers in the light path next to the image pixels. With FT technology on the other hand, pixels are also used to transport the image, so pixels and windows can be relatively larger without gaps between them for shift registers. The result, better performance under all conditions.

Achieving maximum resolution

Horizontal resolution of a sensor is directly related to the number of pixels in a given line. This is static resolution. And to fully resolve a standard television image of 400 TV lines resolution, with minimum alias effects requires at least 700 pixels. With fewer pixels, the higher frequencies that are present will cause aliasing - an interference pattern on fine picture detail.

The new DPM sensor from BTS has 1000 pixels in both 4:3 and 16:9 formats. So aliasing effects are negligible. Whilst competitive sensors also offer 1000 pixels in the 16:9 format, as has already been seen when they are "switched" to 4:3, the pixel count drops to around 720.

In practice, to resolve a frequency being sampled, the sampling rate should be at least twice that of the highest frequency. Lower sampling rates will have artifacts that are within the bandwidth required to be resolved and will be perceived as aliasing.

In the case of sensors, fine detail that is beyond the system bandwidth should be limited in the light path before the sensor. This is normally achieved by optical filters which softly limit high frequency information outside the TV system bandwidth, before it is "seen" by the sensor.

With the Frame Transfer sensor, the relatively large and closely grouped pixels (with their associated high ratio of window aperture to pitch) mean there is inherently less aliasing for a given number of pixels per line.

Other sensors however, with the larger gaps between the pixels caused by shift registers, are not so effective. Alias performance in the luminance channel can be improved by offsetting the red and blue CCD sensors in respect to the green.

This is to enable sampling detail that would otherwise fall outside the resolving capabilities of individual sensors. This technique does not improve resolution in the RGB channels or chroma key performance.

Dynamic resolution - to lag or not to lag

TV is about moving pictures and not static test patterns. The dynamic resolution of a sensor is therefore critical.

Assuming that a sensor has sufficient pixels to resolve the highest frequency for a TV standard under static conditions, what reduces this response under dynamic conditions? Lag.

In Frame Transfer sensors, 100% of the charge in the image pixels is moved to the storage area. So lag is not possible. And dynamic resolution is maximised, providing clean clear film-like pictures.

With other sensors, lag is present, because the charge transfer between the pixels and the vertical shift register is incomplete. This is caused by a small number of electrons accumulated in the image pixels, being left behind after transfer. The amount of lag, therefore being determined by the efficiency of the transfer.

High sensitivity - across all f-stops

The increasing requirement for cameras to perform as multi-role units (with potential outside broadcast lighting problems) requires that sensors maintain high sensitivity under all conditions.

Some sensor designs feature micro lenses located above the sensor pixels. These are intended to focus more of the available light onto the sensitive area, which would otherwise be wasted on non-sensitive shift register elements. On these sensors, shift registers are located with the pixels in the image capture region of the device.

Micro lenses however, can cause problems. These include non-linear sensitivity, a fall-off in resolution plus flare and halos which are the result of irregularties on the surface of sensors with micro lenses.

As the camera lens iris is closed, using higher f-stops, the light falling onto the sensor will be more parallel and the micro lenses will focus more light onto the pixels, as intended. When the camera lens is wide open however, the light falling onto the micro lenses will not be parallel, and thus all available light will not be focussed onto the pixels.

In other words, sensors with micro lenses are least sensitive when the camera lens is wide open - so when maximum sensitivity is needed, it is not available.

BTS Frame Transfer sensor technology guarantees high sensitivity and does not rely on micro lenses on the surface of the sensor. With the FT sensors, efficient conversion of light input to an electrical output is determined by a number of factors such as internal capacitance and size of actual pixel windows.

The result of BTS sensor technology is a sensor that offers the highest linear sensitivity performance.

Extending the BTS commitment (Man nennt es Eigenlob)

The increasing acceptance and use of widescreen television, means without question that the new DPM Dynamic Pixel Management sensors plus the new LDK 10 and LDK 10P (portable) cameras from BTS are going to be playing a leading role.

Needless to say, however, BTS is committed to offering continuing support for our current camera products such as the LDK 9, LDK 9P and LDK 93. This commitment is demonstrated by the availability of wide screen sensors for these cameras too.

With the 1/2 inch wide screen sensor. The first EDTV image sensor that is switchable electronically between 4:3 and 16:9 aspect ratios. Fully meeting EDTV requirements and at the same time offering a cost effective implementation of that performance in SDTV cameras.

BTS 1/2 inch wide screen sensors, giving a proven performance that's characterised by a high dynamic range. And because you are dealing with a Frame Transfer sensor - absolutely no smear and no lag. Whether you are committed to the cameras of today or are planning a commitment to the cameras of tomorrow, BTS sensor technology makes the commitment to go with you.

When you want to switch from 4:3 to 16:9, BTS cameras and FT sensors will switch with you.

Nachtrag : Wenn notwendig, sind die Bilder und Illustrationen simuliert und nicht vom Monitor abgenommen.

.

- Germany Headquarters

BTS Broadcast Television Systems GmbH Robert-Bosch-Strasse 7, D-64293 Darmstadt Tel:+49 6151 808-0 Fax:+49 6151 89 44 63 - Austria

Philips Professionelle Elektronik Ges.m.b.H.

Breitenfurterstrafie251,A-1230Wien - Benelux

Philips Nederland B.V.

Boschdijk 525, NL-5600 PB Eindhoven, The Netherlands - France

S.A. Philips I.C., Division BTS

41 Rue de Verdun, F-92156 Suresnes Cedex - Italy/Greece

BTS Broadcast Television Systems SRL Via Valentino Mazzola 66,1-00142 Roma - The Netherlands

BTS Broadcast Television Systems BV

P.O. Box 90159,4800 RP Breda - Spain and Portugal

Philips Telecommunications, S.A.

Martinez Villergas 2, E-28027 Madrid - Switzerland

Philips Communications Systems AG Cable Transmission and Networks Allmendstrasse 140, CH-8027 Zurich - United Kingdom

BTS Broadcast Television Systems (UK) Ltd.

Theale Cross, Pincents Kiln, Calcot Reading, Berkshire RG3 7SD - USA/Canada

BTS Broadcast Television Systems Inc.

94 West Cochran Street, Simi Valley, CA 93065, USA

.

© Copyright BTS Breda BV 1994.

.